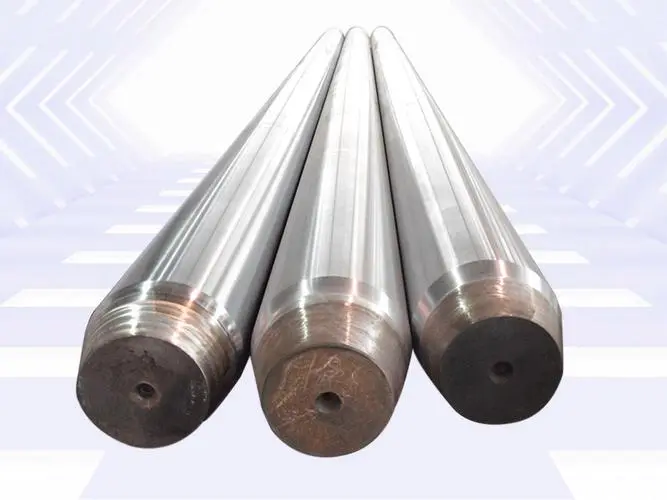

Mandrel wani nau'in nau'in nau'in gyare-gyare ne da ake amfani da shi don samar da filaye na kwane-kwane a cikin hanyar latsawa a cikin billet ko jikin da ba a so. An fi amfani da shi don lankwasa bututun ƙarfe, wanda ake samu ta hanyar Mandrels na injin lankwasawa. Wadannan mandrels sun ƙunshi abubuwa da yawa, ciki har da samfura na sama, ƙananan samfuri, wukake masu ƙarfi, da dai sauransu, kuma ana samun lanƙwasa bututun ƙarfe ta hanyar matsa lamba da tsarin watsawa.

Ana iya yin amfani da mandrels na yau da kullun don maganin zafi a cikin nau'in akwatin ko nau'in juriya na rijiyar, amma tsarin yana da rikitarwa kuma yanayin yanayin zafi yana da tsawon kwanaki 2-3, yana buƙatar dumama da rufi na dogon lokaci. Lokacin kashewa, dole ne a gudanar da maganin kashe mai, wanda ke haifar da ƙura da hayaki mai yawa, kuma yanayin aiki a wurin yana da tsauri; Bayan maganin zafi, aikin aikin yana da saurin lalacewa da lankwasawa, kuma dole ne a daidaita shi akan babban latsawa na hydraulic tonnage, yana haifar da farashin masana'anta. Matsakaicin iyaka mai tsayin motsi Retained Mandrel da aka yi amfani da shi a ci gaba da bututun bututu kayan aiki ne mai mahimmanci don mirgina manyan bututun ƙarfe maras sumul don hakar mai da sufuri.

Mandar da aka riƙe shine nau'in mandrel na gama gari akan kayan aikin injin CNC, wanda galibi ana amfani dashi don haɓaka daidaiton injina da kwanciyar hankali a cikin tsauraran matakan injin.

Mandar da aka riƙe yana da halaye masu zuwa

1. Ƙimar ƙarfin ƙarfin da aka riƙe: Abin da ake kira "motsi mai iyaka" yana nufin ƙananan motsi na gaba na ƙarshen da aka riƙe a cikin wani yanki, sa'an nan kuma ƙarfin Mandrel Retained yana iyakance ta hanyar ƙuntatawa. bangaren. Wannan ƙira na iya guje wa wuce gona da iri na motsi da aka riƙe, don haka inganta daidaiton injina da kwanciyar hankali.

2. Dace da m machining: riƙe mandrels yawanci amfani da m machining, kamar hakowa, reaming, m, da dai sauransu A wannan batu, da rike mandrel za tam riko da workpiece don tabbatar da kwanciyar hankali da daidaito a lokacin da machining tsari.

Lokacin aikawa: Jul-03-2024