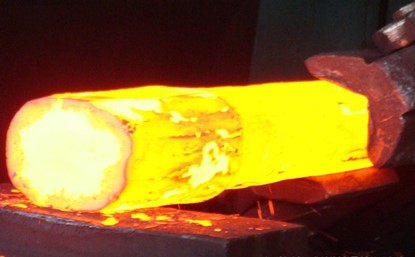

A cikin tsarin ƙirƙira, tashin hankali yana nufin nakasar kayan aiki don ƙara diamita ta matsawa tsayinsa. Muhimmin siga a cikin bacin rai shinerabo daga tsawo zuwa diamita (rabo na H/D), wanda ke taka muhimmiyar rawa wajen ƙayyade ingancin samfurin ƙarshe da yuwuwar tsarin. Ana amfani da rabon tsayi-zuwa diamita don tabbatar da nakasar ta ci gaba da kasancewa mai sarrafawa kuma ta zama iri ɗaya, tare da hana al'amura kamar tsutsawa, fashewa, ko gazawar abu.

Menene Girman Tsawo zuwa Diamita?

Matsakaicin tsayi-zuwa diamita (rabo H/D) shine rabo tsakanin tsayi (ko tsayi) na aikin aikin da diamita kafin ƙirƙira. Wannan rabo yana taimaka ma'anar nawa abu zai iya zama nakasu ta hanyar bacin rai. Yawanci, ƙarami rabon, mafi yuwuwar aiwatar da tashin hankali ya zama saboda guntu, kauri kayan iya jure mafi girma matsawa karfi ba tare da buckling ko tasowa lahani.

Misali, ƙananan rabo na H/D, kamar 1.5: 1 ko ƙasa, yana nuna kayan aiki mai tsauri, wanda zai iya ɗaukar nauyi mai nauyi ba tare da babban haɗarin rashin kwanciyar hankali ba. A gefe guda, rabo mafi girma, kamar 3: 1 ko fiye, zai buƙaci ƙarin la'akari da hankali, yayin da aikin aikin ya zama mai sauƙi ga lahani.

Yadda za a Ƙayyade Mafi kyawun Matsayin H/D?

Madaidaicin ma'auni na H/D ya dogara da dalilai da yawa, gami da kaddarorin kayan, yanayin zafin kayan lokacin ƙirƙira, da matakin nakasar da ake buƙata. Anan ga manyan matakai don tantance mafi kyawun rabon H/D don bacin rai:

- Kayayyakin Kayayyaki: Daban-daban kayan nuna daban-daban matsawa ƙarfi da ductility. Abubuwa masu laushi, irin su aluminium, na iya jurewa ƙarin nakasawa ba tare da tsagewa ba, yayin da abubuwa masu wuya kamar babban ƙarfe na carbon na iya buƙatar ƙaramin rabo na H/D don guje wa yawan damuwa. Matsakaicin kwarara na kayan, watau, damuwa da ake buƙata don ci gaba da lalata kayan ta filastik, dole ne a yi la'akari da shi.

- Yanayin Zazzabi: Ana yin ƙirƙira mai zafi a yanayin zafi wanda ke haɓaka ductility na kayan kuma yana rage ƙarfin da ake buƙata. Maɗaukakin yanayin zafi yana ba da izini ga nakasa mafi girma, wanda ke ba da izinin girman girman tsayi zuwa diamita. Don ƙirƙira sanyi, ƙimar H/D ya kamata a kiyaye ƙarami saboda ƙara haɗarin aiki da tsagewa.

- Digiri na nakasa: Adadin nakasar da ake buƙata wani muhimmin al'amari ne. Idan ana buƙatar raguwa mai mahimmanci a tsayi, farawa tare da ƙananan rabo na H / D yana da amfani don tabbatar da aikin aikin zai iya jurewa matsi da ake buƙata ba tare da lahani ba.

- Gujewa Lalacewar: Lokacin ƙayyade rabo na H / D, yana da mahimmanci don kauce wa lahani irin su buckling, wanda ke faruwa a lokacin da kayan folds ko wrinkles a lokacin matsawa. Don guje wa ɓarna, ƙa'idar babban yatsan hannu ita ce a yi amfani da rabon H/D na farko na ƙasa da 2:1 don ƙirƙira bacin rai gaba ɗaya. Bugu da ƙari, lubrication da ƙirar mutuƙar da ta dace suna da mahimmanci don rage juzu'i da tabbatar da nakasar iri ɗaya.

Misali Mai Aiki

Yi la'akari da yanayin tayar da silinda na ƙarfe na ƙarfe. Idan farkon tsayin billet ɗin shine 200 mm kuma diamita shine 100 mm, rabon H/D zai zama 2: 1. Idan kayan yana da ɗan laushi, kuma ana amfani da ƙirƙira mai zafi, wannan rabon na iya zama karbabbe. Koyaya, idan an yi amfani da ƙirƙira sanyi, rage tsayi don rage ƙimar H/D na iya zama dole don guje wa ɓarna ko fashewa yayin aiwatar da tashin hankali.

Kammalawa

Matsakaicin tsayi-zuwa diamita a cikin bacin rai shine muhimmin al'amari na ƙirƙira wanda ke ƙayyade nasarar aikin. Ta hanyar kimanta kaddarorin kayan a hankali, zafin jiki, da buƙatun nakasar, za a iya kafa madaidaicin rabo, yana tabbatar da samar da ingantattun ingantattun abubuwan ƙirƙira marasa lahani.

Lokacin aikawa: Satumba-18-2024